90° Peeling Test for Adhesive Tapes [Standard No. ISO 29862:2007 (JIS Z 0237:2009)]

As the chemical industry has developed, adhesives using synthetic polymers as raw materials have been commercialized. These adhesives are often used in a variety of industrial fields, including electronics and electrical machinery. This article introduces an example of a 90° peeling test for adhesives used in adhesive tapes.

Measurements and Jigs

The sample was an ordinary adhesive tape cut to a width of 24 mm and a length of 300 mm; it was set on a SUS304 stainless steel plate. An adhesive tape peeling test attachment, which is capable of peeling off tape at an angle of 90° from the plate on which the sample was set, was used as the test jig.

Measurements Results

Fig. 1: Peeling Test

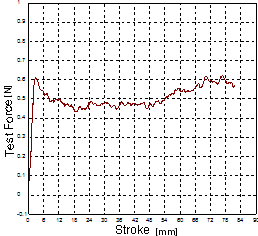

Fig. 2: Relationship between the Test Force and Stroke

The test was implemented at a loading speed of 300 mm/min. After measurement started, measurement values for the initial length of 25 mm were discarded. Afterwards, the adhesive force measurement values for a length of 50 mm peeled off the plate were averaged. This average value was taken as the peeling adhesive force.

| Peeling Adhesive Force |

| 0.238 N/10 mm |

Tensile Testing System for Plastic Materials

| Tester | AGS-X |

| Load Cell | 50 N |

| Testing Jig | Adhesive tape peeling test attachment |

| Software | TRAPEZIUM LITE |

- A high-precision load cell is adopted. (The high-precision type is class 0.5; the standard-precision type is class 1.)

Accuracy is guaranteed over a wide range, from 1/500 to 1/1 of the load cell capacity. This supports highly reliable test evaluations. - Crosshead speed range

Tests can be performed over a wide range from 0.001 mm/min to 1,000 mm/min. - High-speed sampling

High-speed sampling, as fast as 1 msec. - TRAPEZIUMX LITE X operational software

This is simple, highly effective software. - Jog controller (optional)

This allows hand-held control of the crosshead position. Fine position adjustment is possible using the jog dial. - Optional Test Devices

A variety of tests can be conducted by switching between an abundance of jigs in the lineup.