AP Series - Anwendungen

Analytical Balances

Most of the documents on the LITERATURE is available in PDF format. You will need Adobe Acrobat Reader to open and read PDF documents. If you do not already have Acrobat Reader, you can download it free at the Adobe's Website. Click the GET ADOBE READER icon on the left to download a free copy of Adobe Acrobat Reader.

For HPLC - Fpr Users of HPLC Systems

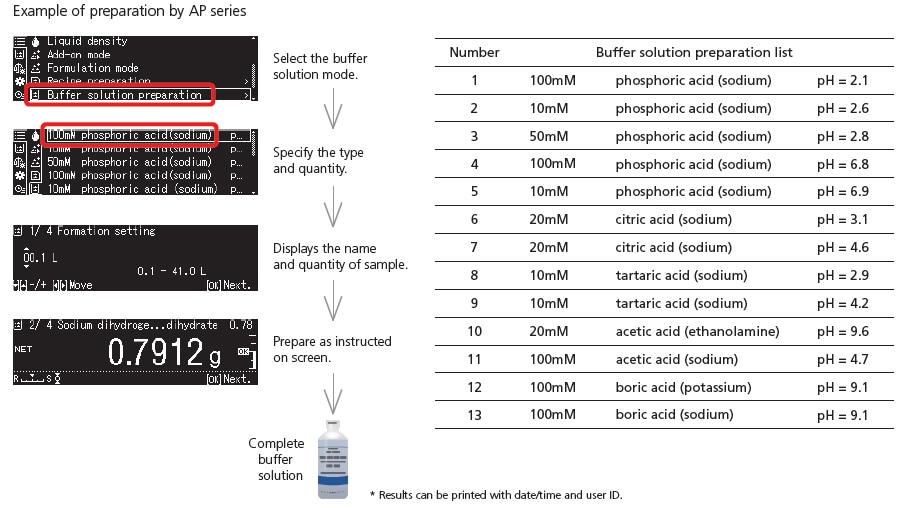

Buffer Solution Preparation Mode(AP-W Series only)

- Recipes for 13 commonly used buffer solutions are included as standard

Preparation recipes for commonly used buffer solutions are provided as standard.

e.g. disodium phosphate, sodium acid citrate - New buffer solution recipes can be registered

If a buffer solution is not registered by default, it can be newly registered. - Instructions are shown on the display

The target weighing value is shown on the display and analog bar in order to compare the target with the current weight. Manual calculation is not needed. - Record function

Record output with date, time and operator name.

The pH level of mobile phase (eluent) solutions used in liquid chromatographs is adjusted to improve separation of components and extend the life of columns. This pH adjustment process is performed using a buffer solution.

Currently, the most common method is using a pH meter to measure the pH as the solution is prepared; however, this process requires considerable time and effort, which can cause operational bottlenecks.

An alternative method does not require a pH meter. It involves preparing solutions by weighing fixed theoretically calculated quantities of an acid and base.

AP series supports weighing these acids and bases. If the type and quantity of the buffer solution are specified, the balance displays the type and quantity of sample that should be weighed. Then the buffer solution can be prepared easily by adding water to the specified quantity of sample weighed accordingly.

Preparation example:

When weighing and preparing 50 mM of di-sodium hydrogen phosphate, 2-hydrate and 50 mM of sodium dihydrogenphosphate, 2-hydrate in order to prepare 3 L of 100 mM phosphoric acid (sodium) buffer solution at pH=2.1:

For Regulation-for the Pharmaceutical Industry

High-Security User Management

Operations can be kept secure with user ID and password protection. Access rights can be specified separately for each user to prohibit unauthorized actions such as performing calibration or changing the settings. User IDs can also be used for barcode management.

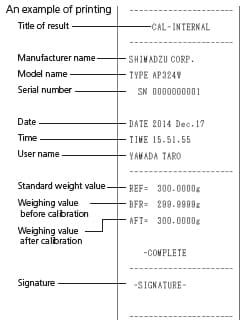

Printing Data in Accordance with Various Regulations

Printing can be customized to indicate when the measurements were taken and by whom. Users are free to set which items are to output, and in what order. The date, time, calibration log, and other information can be printed depending on the purpose of printing, which supports compliance with ISO, GLP, and GMP.

- Date

- Time

- User name

- Balance manufacturer name

- User ID

- Serial number

- Balance ID

- Software version

- Minimum sample quantity

- Blank line

- Ruled line (--------)

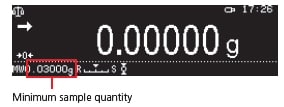

Minimum Measurement Value (Warning Function)

Reproducibility can be confirmed by repeatedly measuring weights as instructed by AP series. The minimum sample quantity is automatically determined from the standard deviation and recorded in AP series. If the minimum sample quantity requirement is not satisfied during measurement, an indicator flashes to warn the user.

Recipe Function (Achieve Your Preferred Compounding Process)(AP-W Series only)

Sample recipes can be registered, allowing users to simply follow displayed instructions. This is convenient when compounding medicines.

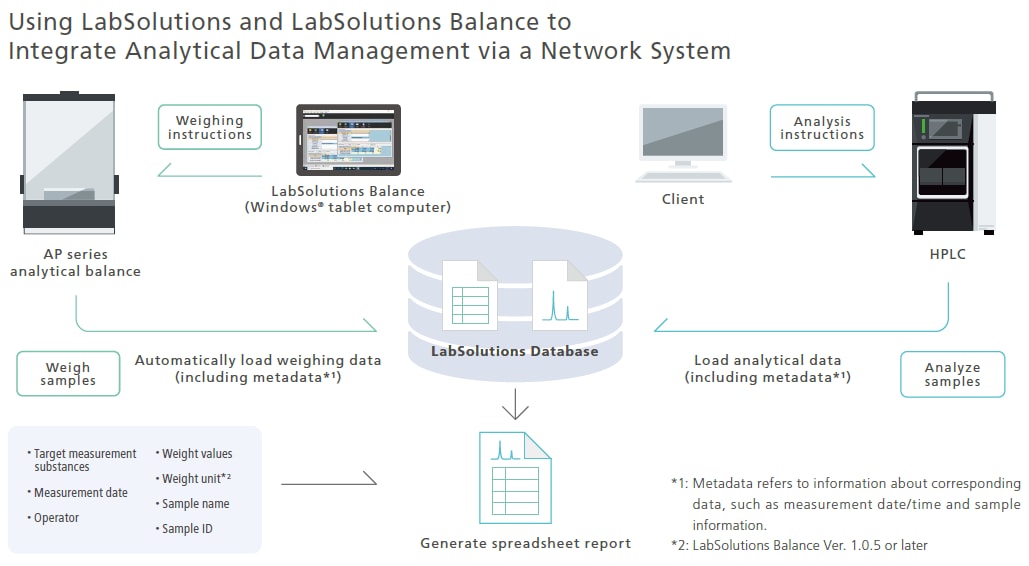

Solutions to Improve Operational Efficiency and Ensure Data Reliability LabSolutions Balance Analytical Network Data System Compliant with ER/ES Regulations

- LabSolutions Balance eliminates the need to enter weighing data manually and the risk of transcription errors.

All weighing data is saved in a safe database. - A spreadsheet report of tamper-proof weighing data and analytical data is automatically created.

- Spreadsheet reports can also be customized to customer requirements, such as by combining weighing data with HPLC or other analytical results for system suitability tests, content uniformity tests, or elution tests.